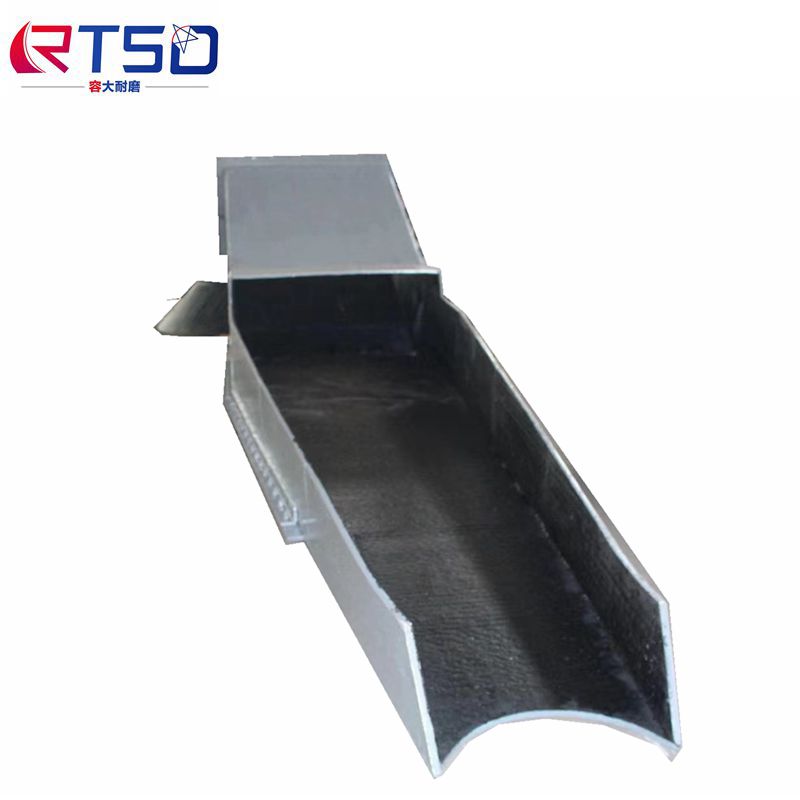

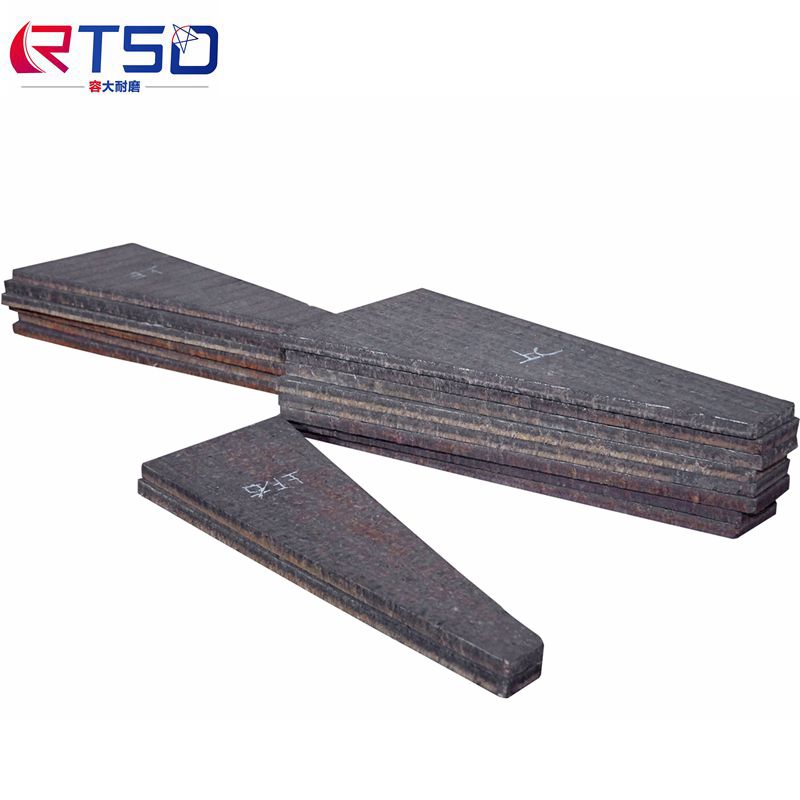

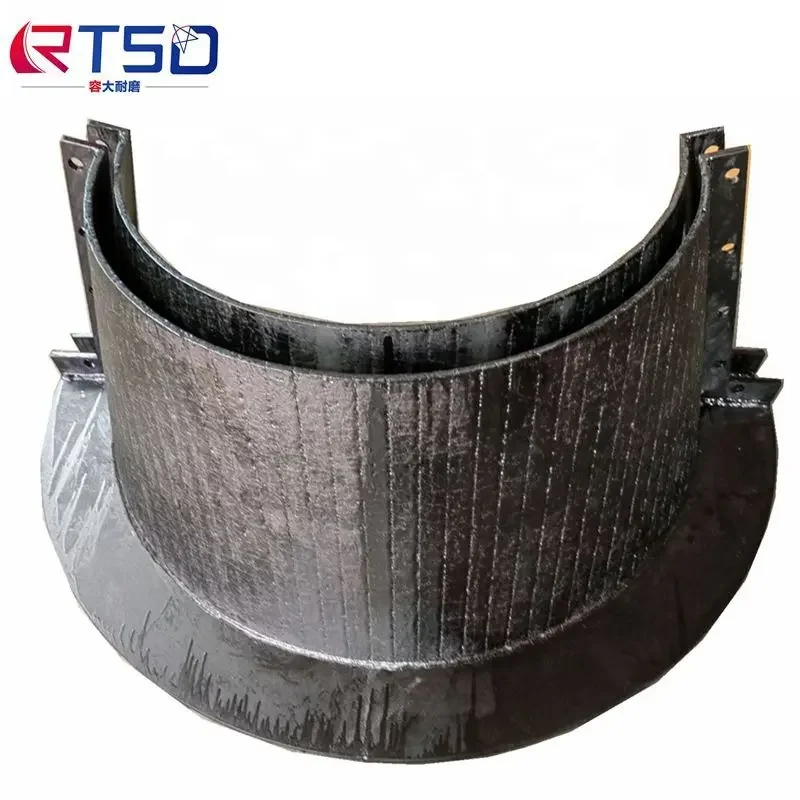

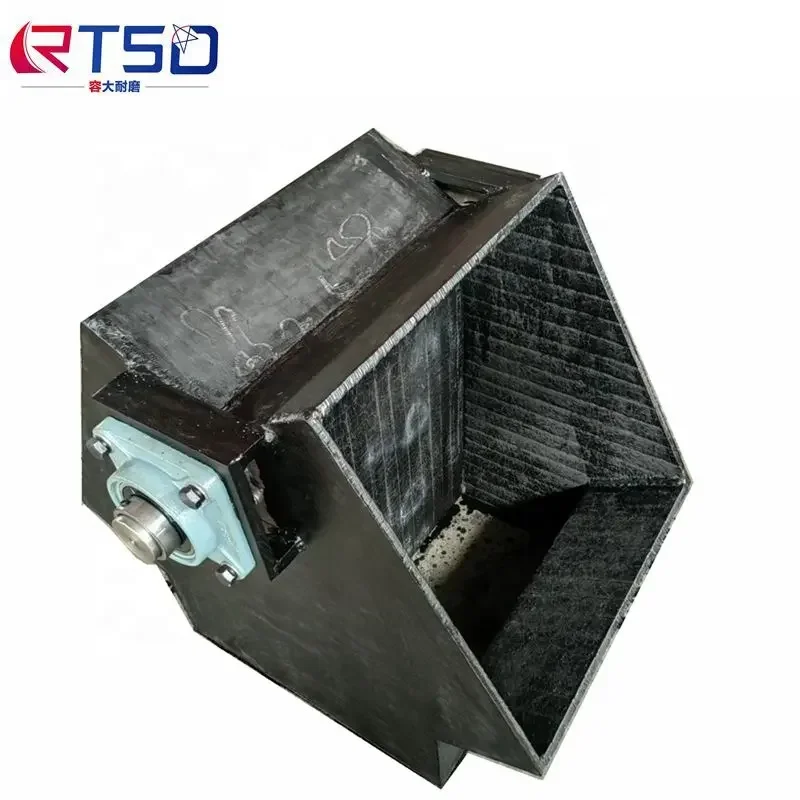

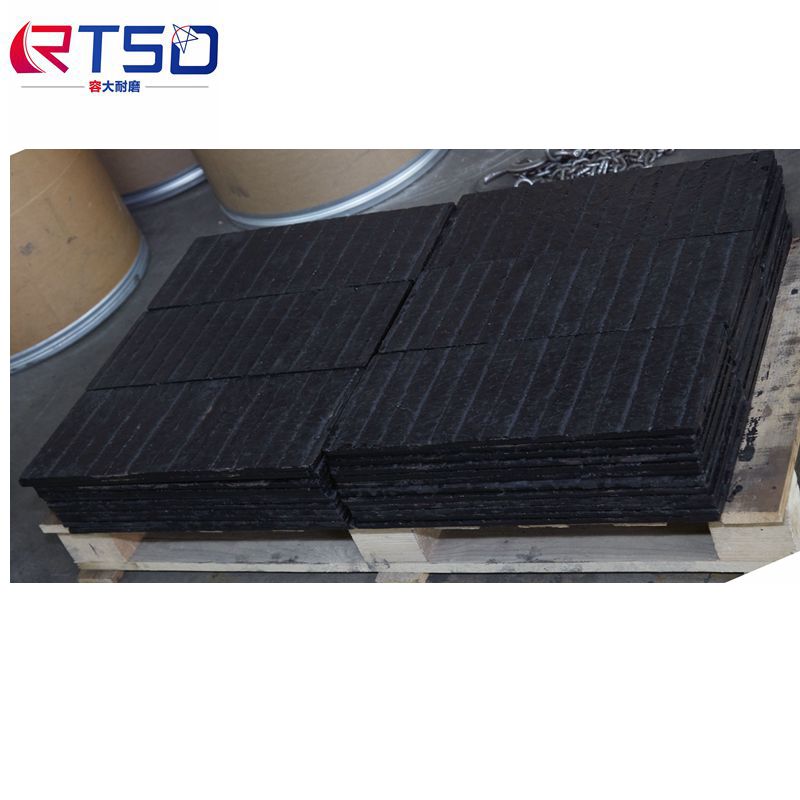

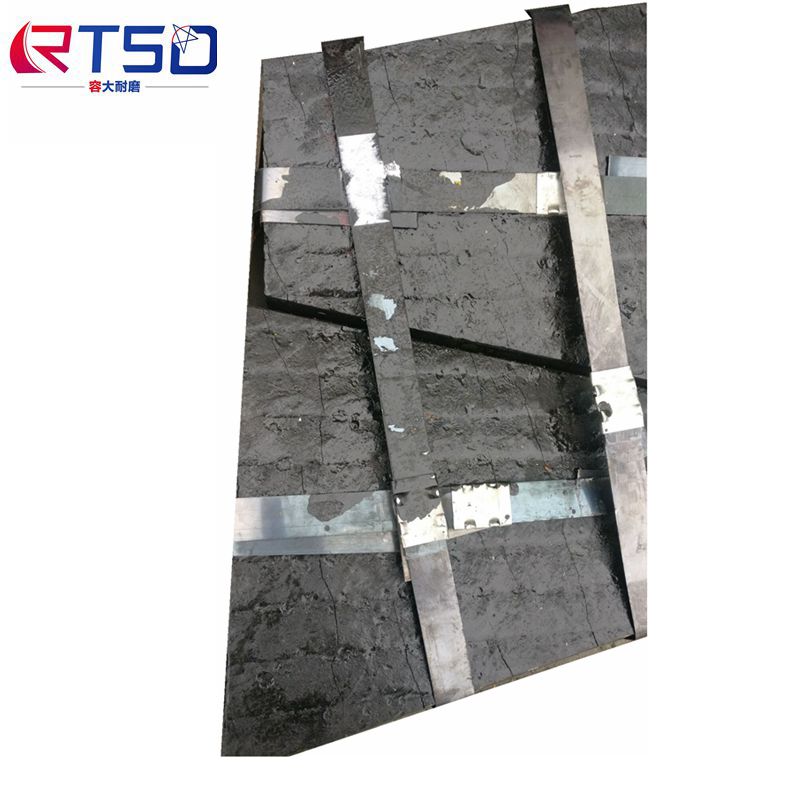

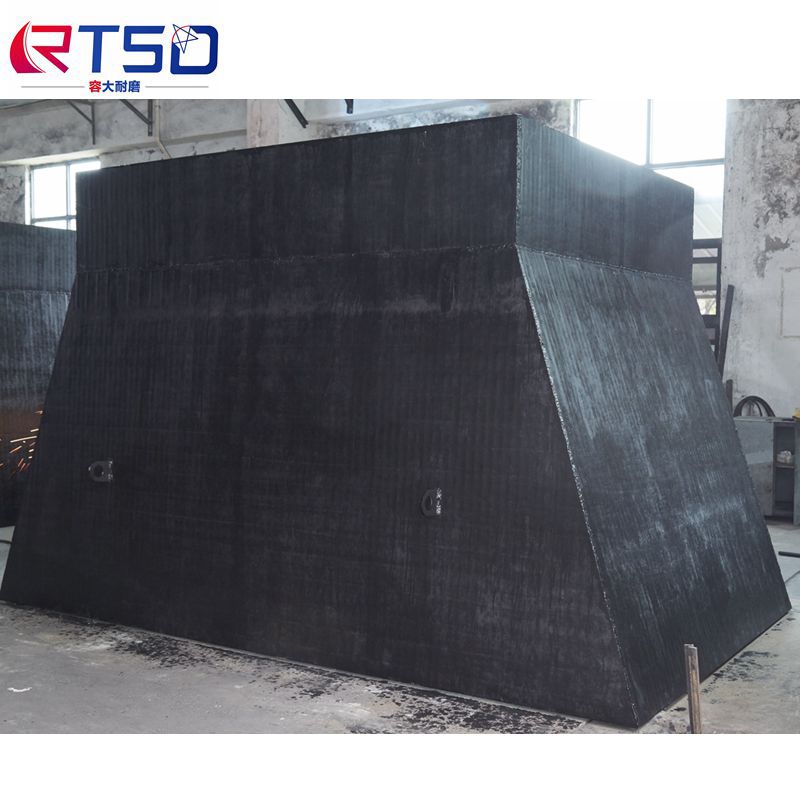

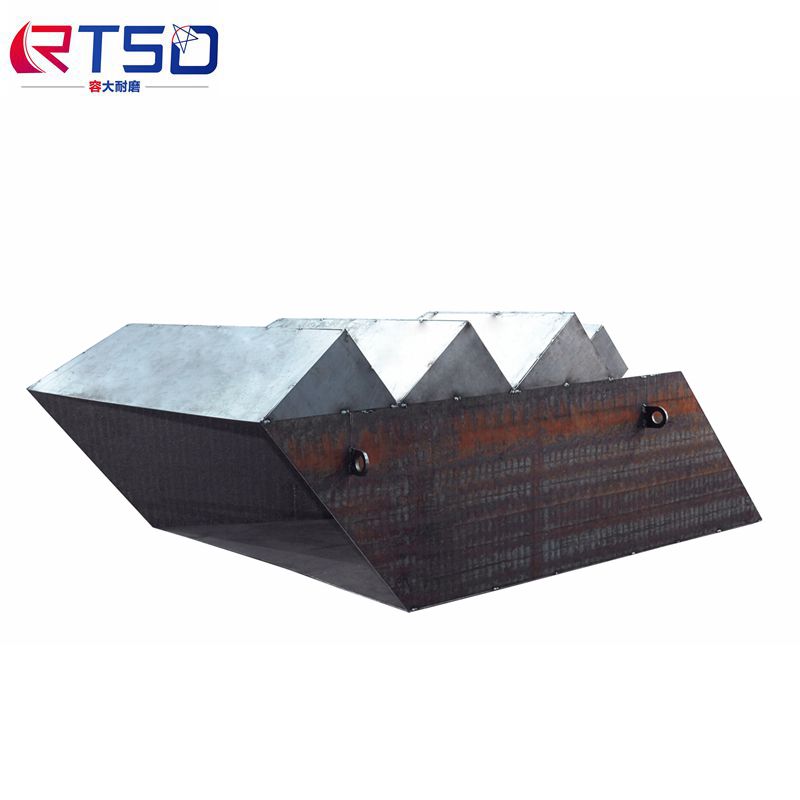

High chrome surfacing wear-resistant steel plate workpieces parts

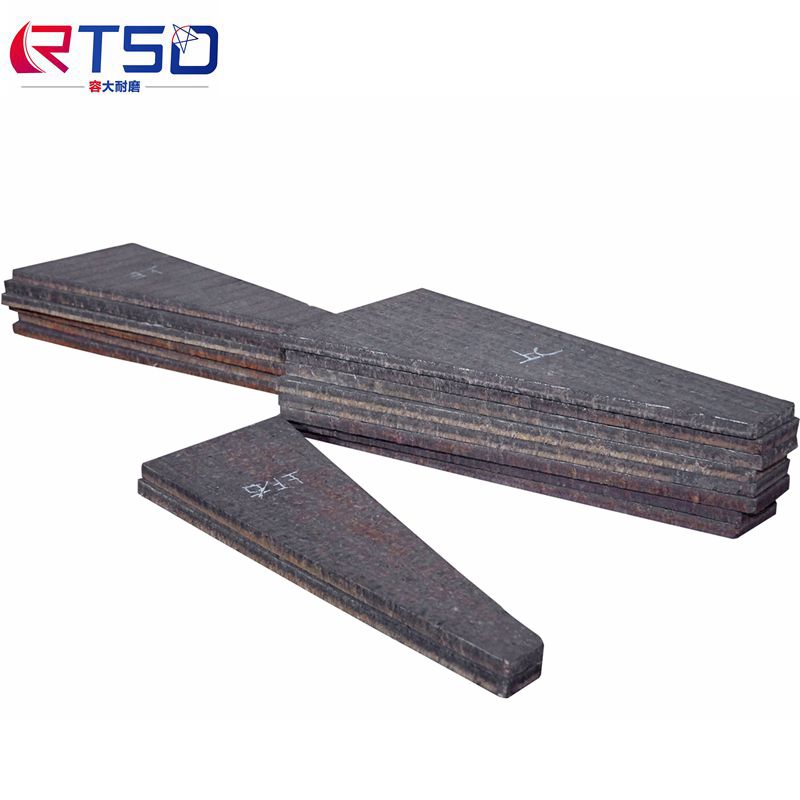

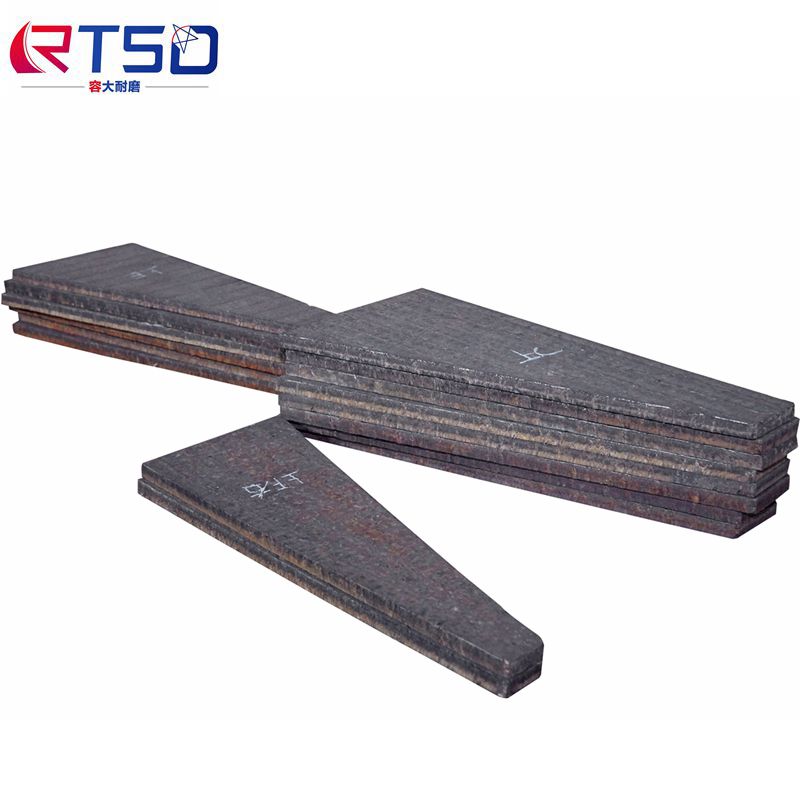

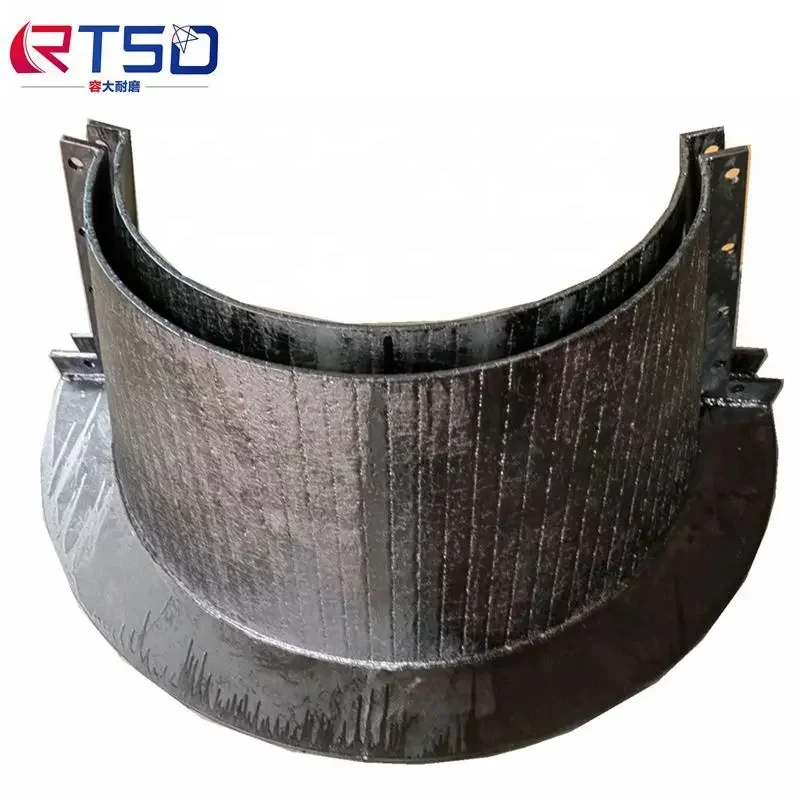

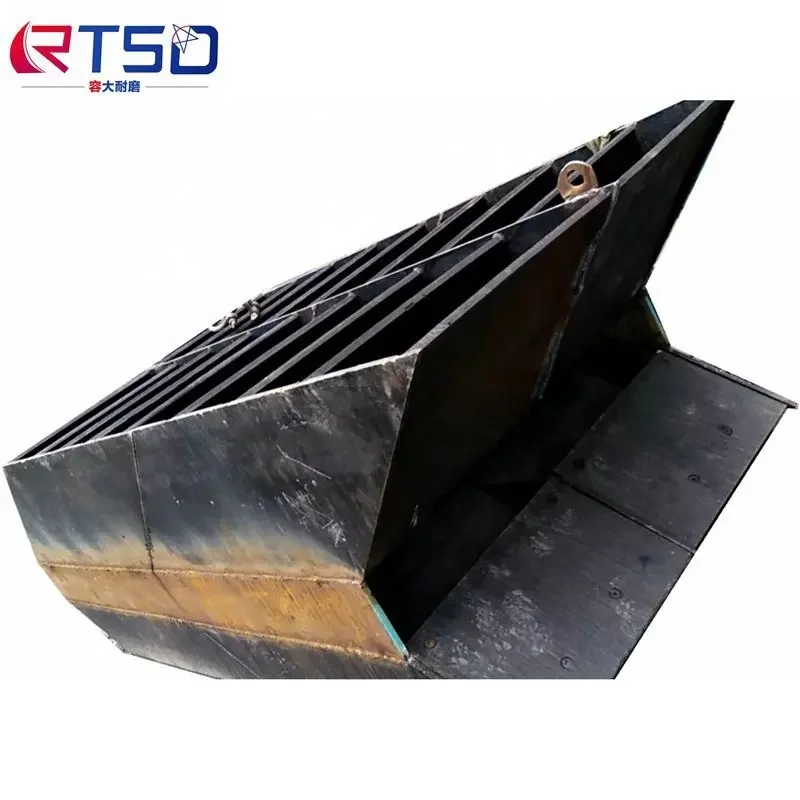

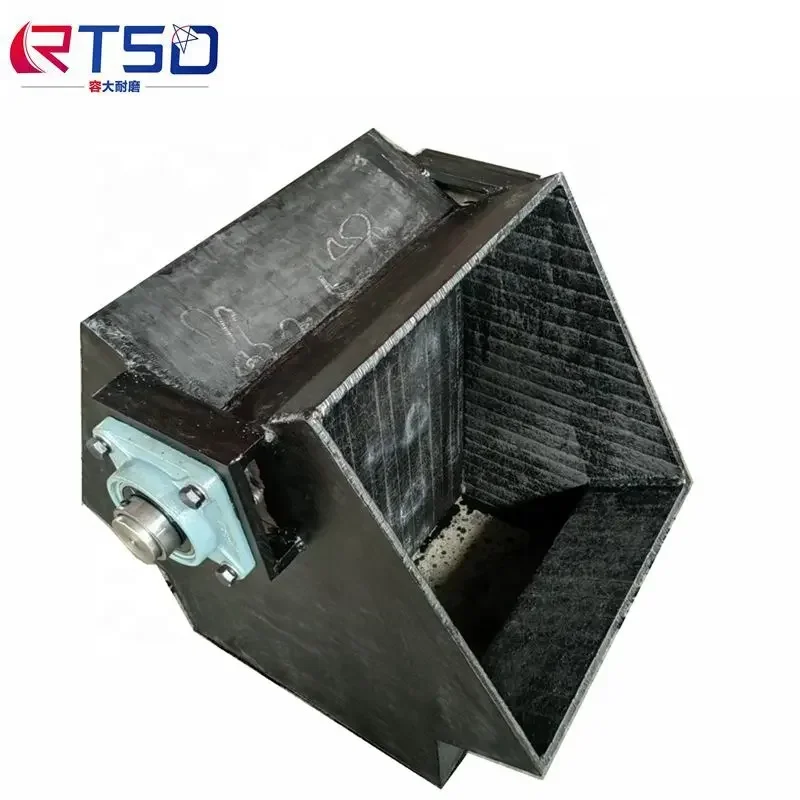

RTSD high chrome surfacing wear plate has a good cutting, roll round again proce

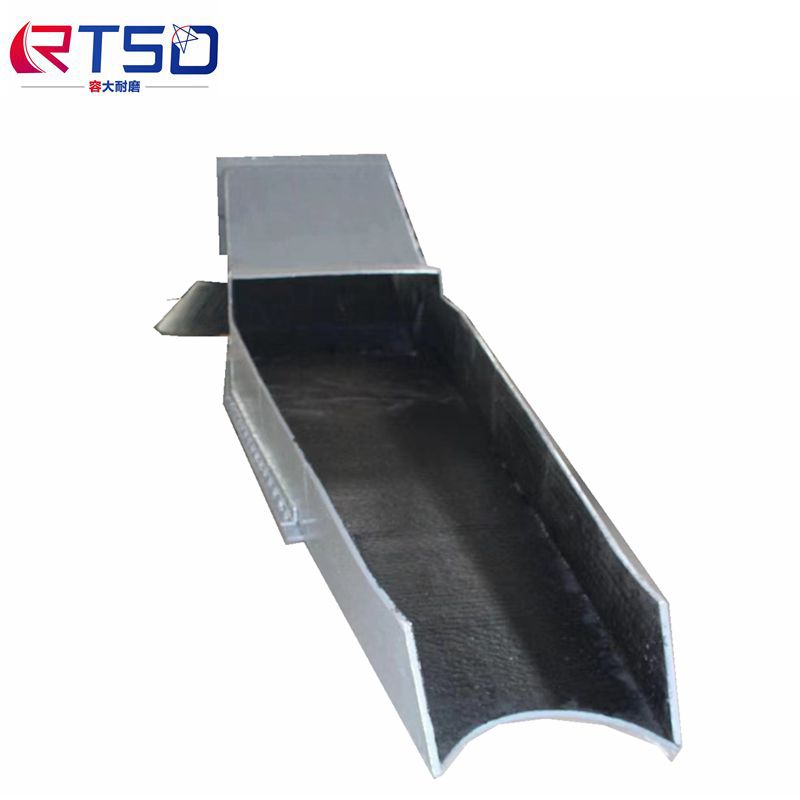

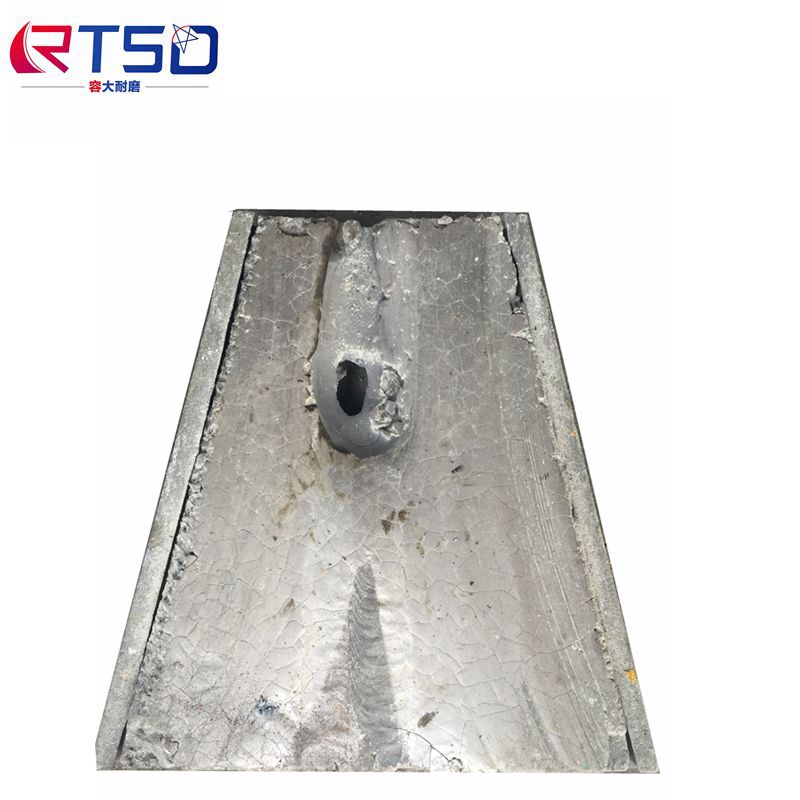

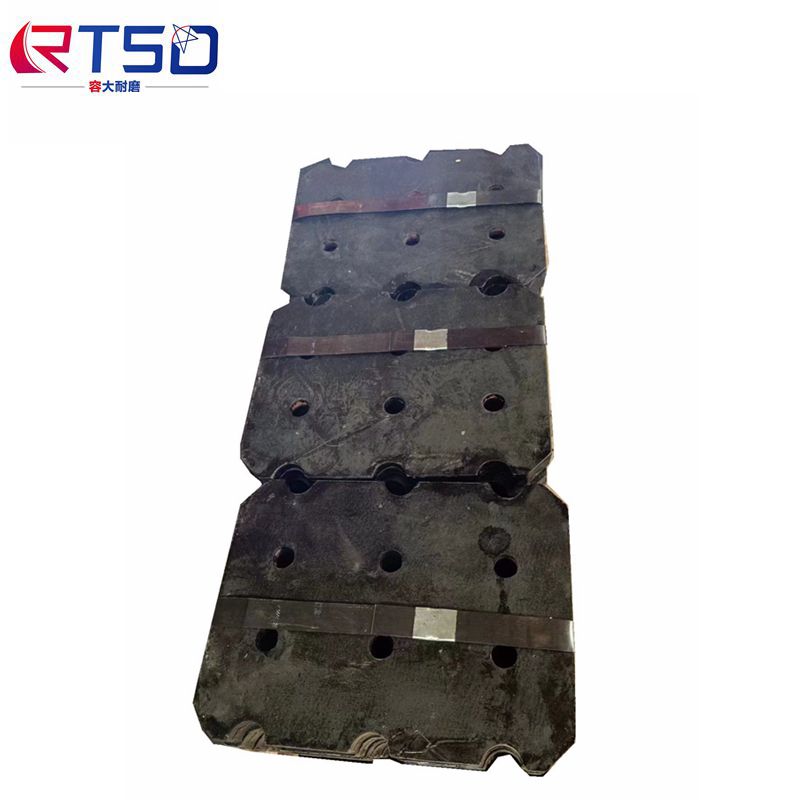

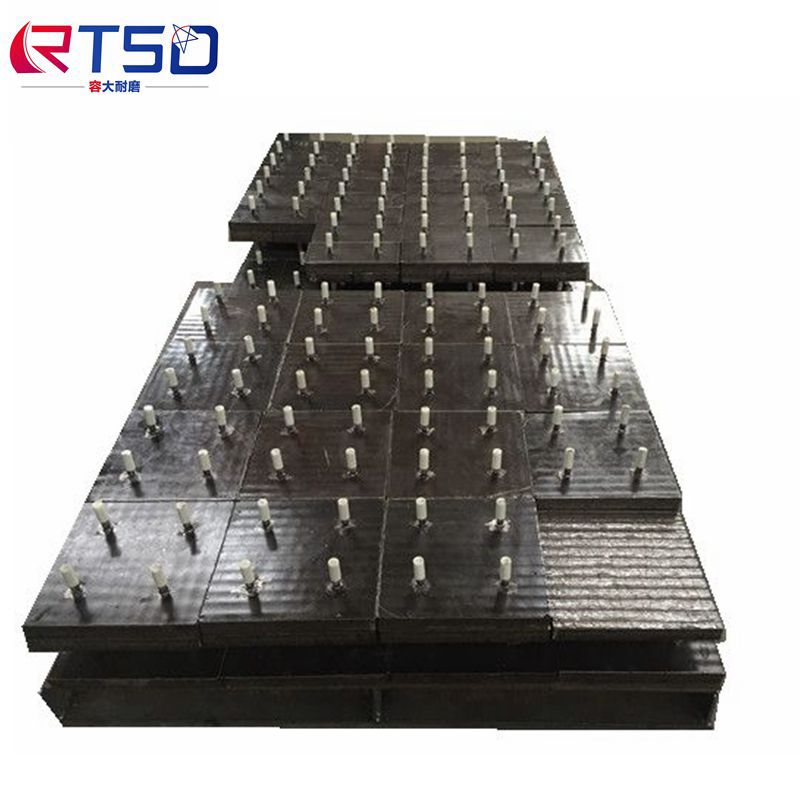

RTSD high chrome surfacing wear plate has a good cutting, roll round again processing function, according to the specific needs of customer working conditions can be processed into the ideal shape, to achieve better wear-resistant, impact-resistant function. RTSD high chrome surfacing wear-resistant processed parts can be widely used in the cement, electric power, iron and steel, papermaking, mining, coal processing, glass industry, and so on. It provides a good choice for the customers in the working conditions with high abrasion and wear, and effectively reduces the downtime caused by frequent abrasion and environmental pollution.

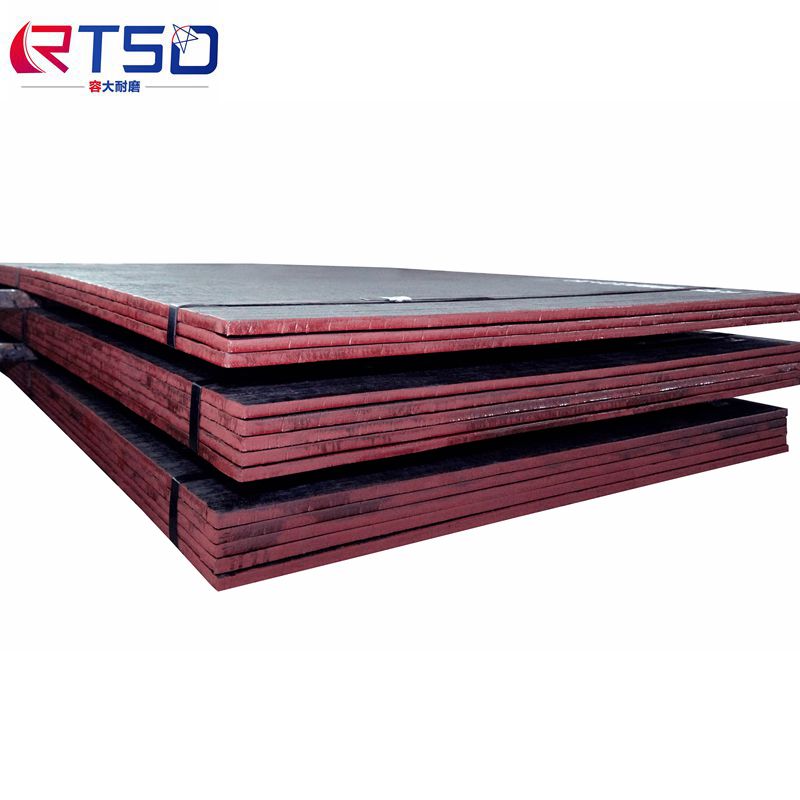

Hardfacing Chromium Carbide Overlay (CCO) Wear Plate, mainly used for resist abrasion and impact, protect and prolong the life ofthe process production equipment.

are commonly used in industries such as Mining, Iron Mill/Steel Plant, , Thermal Power Industry, Chemical industry,. Cement, Construction Machinery etc., where heavy equipment and machinery are subject to intense wear and tear.

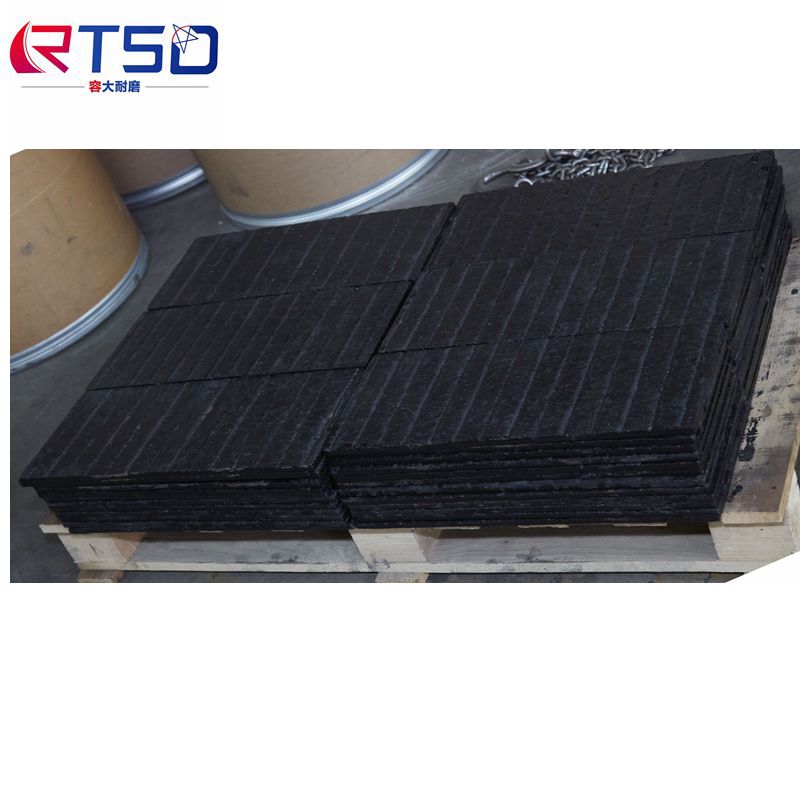

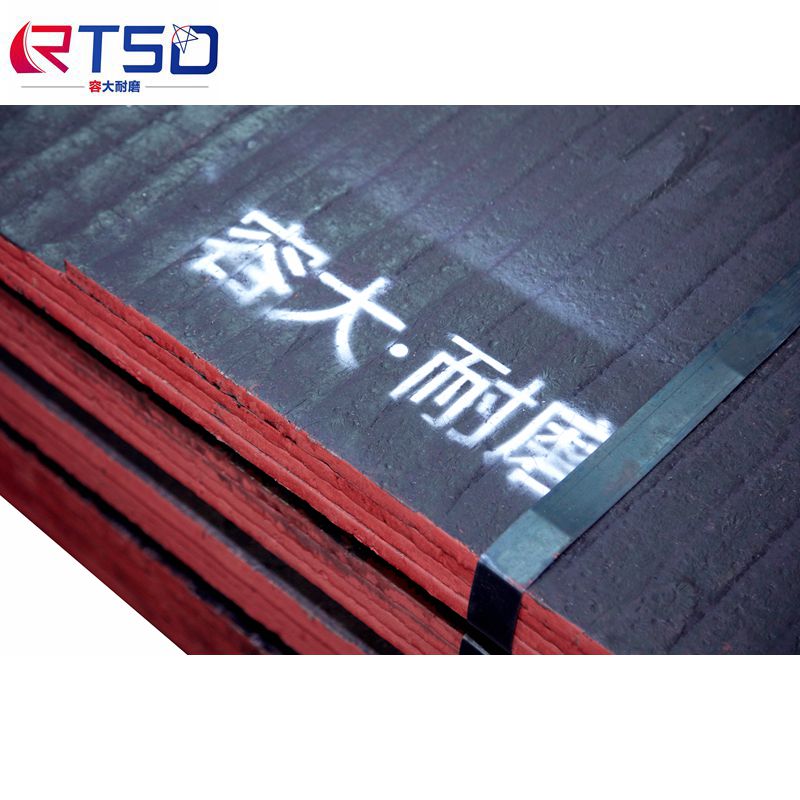

Have you ever heard of RTSD WEAR PLATE®? It is a high performance composite hardfaced wear plate made from hard and high-strength alloys, that are designed to resist abrasion, impact, erosion and other forms of damage that can be caused by heavy use.

They are commonly used in industries such as Mining, Iron Mill/Steel Plant, , Thermal Power Industry, Chemical industry,. Cement, Construction Machinery etc., where heavy equipment and machinery are subject to intense wear and tear.

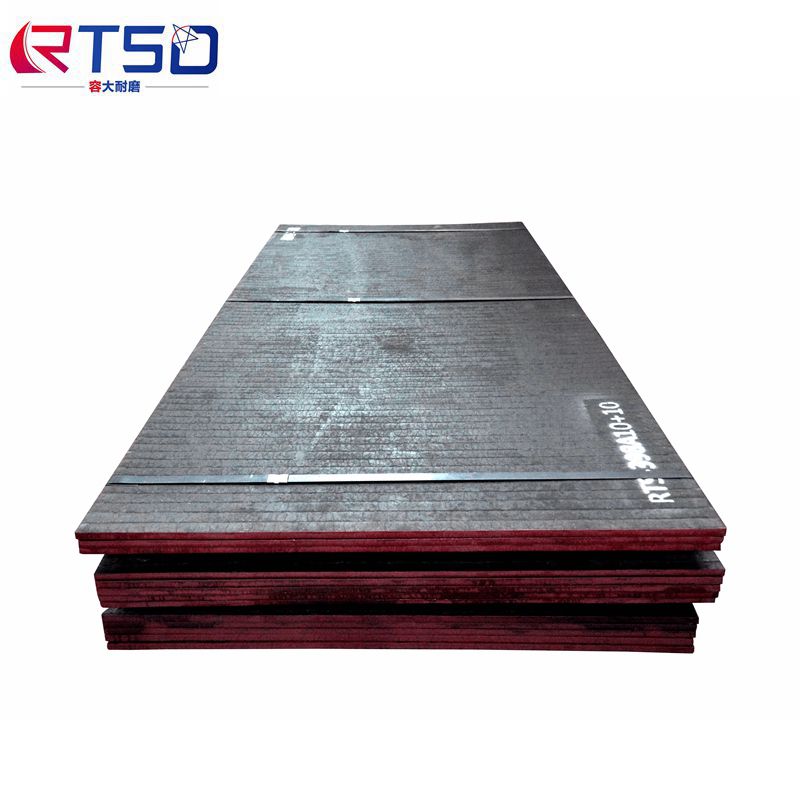

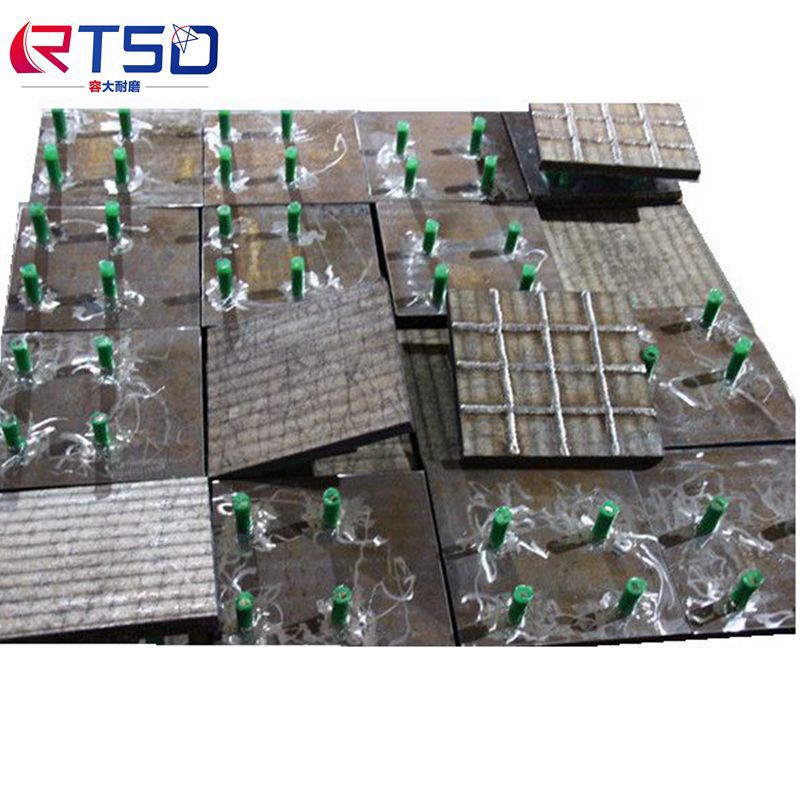

In addition to their durability, RTSD WEAR PLATE® plates are also highly customizable. They can be manufactured in a variety of shapes, sizes, and thicknesses to fit the specific needs of different industries and applications.

So, if your equipment and plant units are subject to severe industrial wear, consider using hardfaced plates. Your equipment will thank you!

| Product Name | RTSD hot sale Wear resistant composite thick size steel Wear resistant steel suitable for coal mines |

| Brand | RTSD |

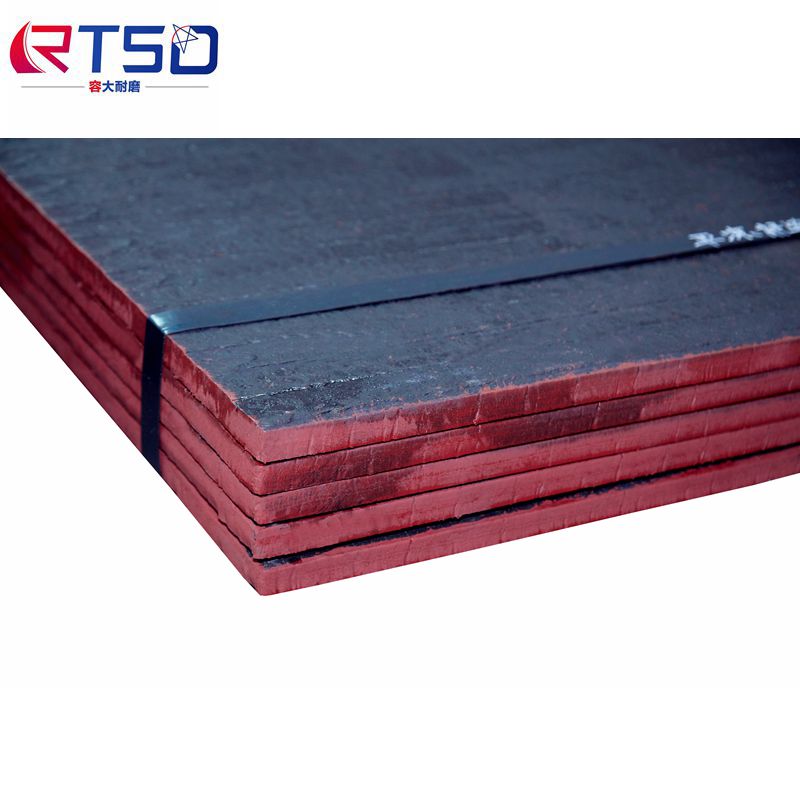

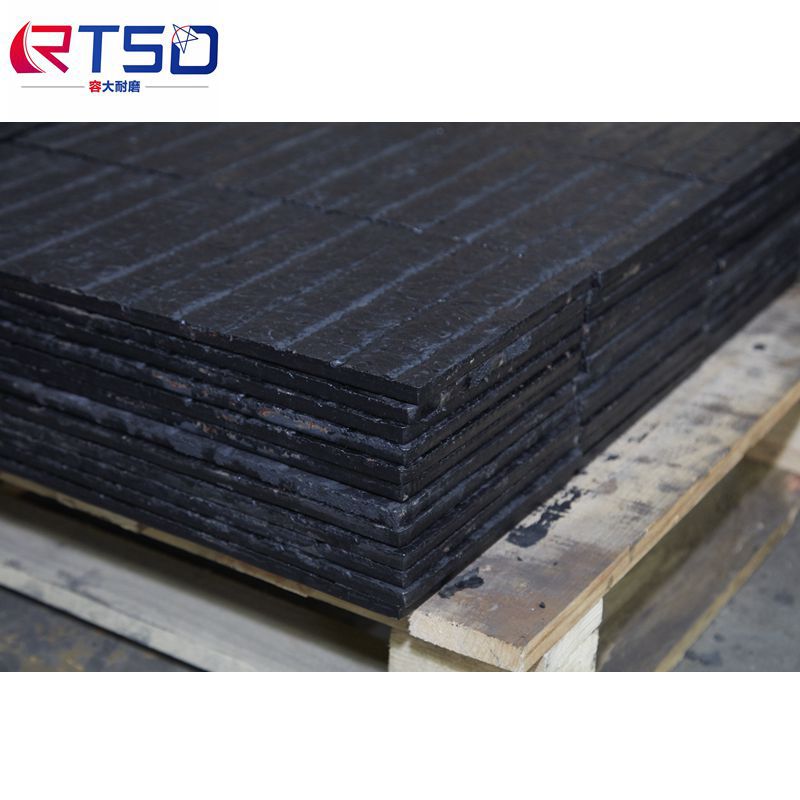

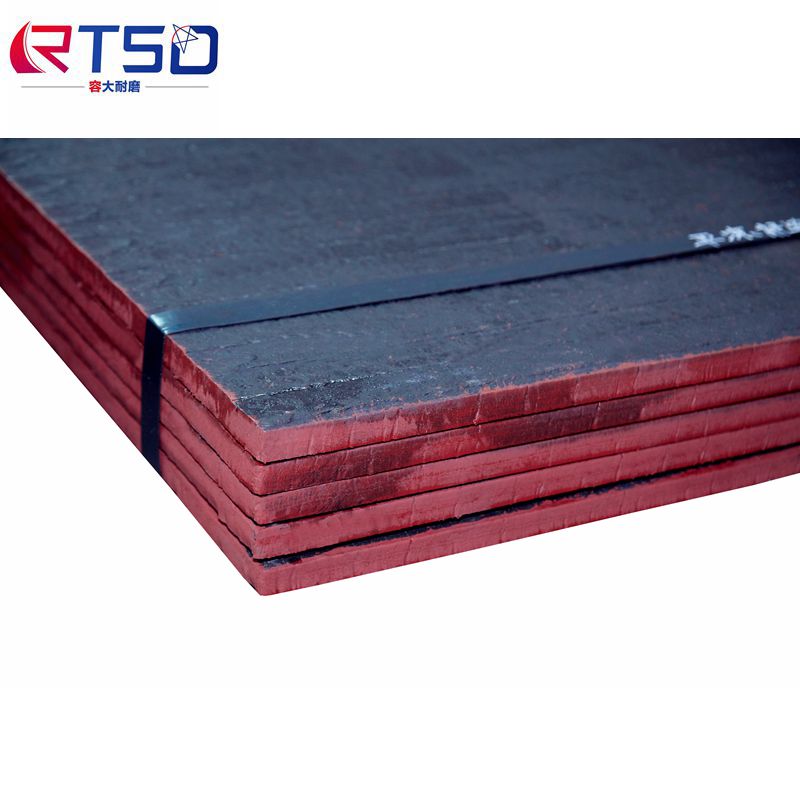

| Base Plate | Q235/Q345 |

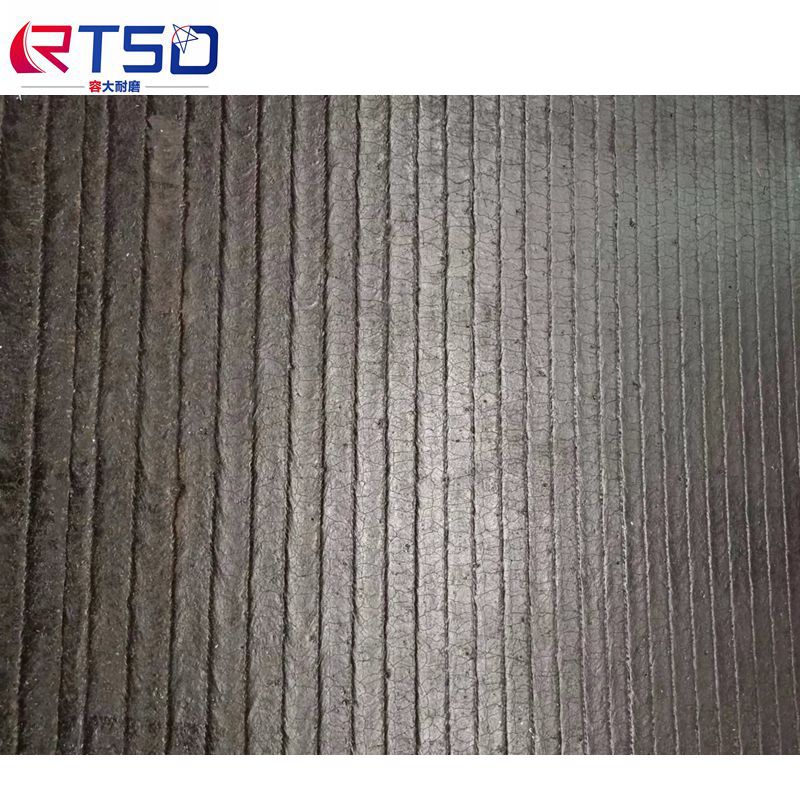

| Hardfacing layer | High chromium high carbide overlay |

| Chemical Composition | C(%): 3.0-5.0 ,Cr(%): 25-40 |

| Microstructure | The carbide (Cr7C3) volume fraction on the microstructure is above 50% |

| Hardness | HRC58-65 |

| Surface Treatment | Hardfacing,clading,coated |

| Technique | Hardfacing,open arc welding,submerged arc welding |

| Wear Resistance | High wear resistance,30 times higher than low carbon steel and 12 times than heat treated steel |

| Impact Resistance | Medium |

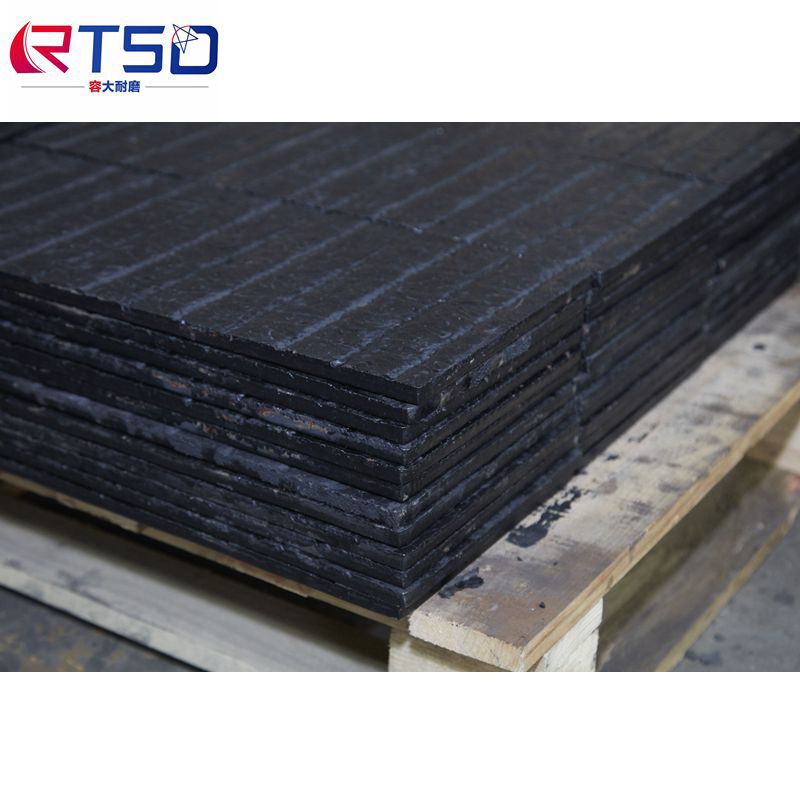

| Flatness tolerance | ±3mm/m |

| Thickness tolerance | Uniform overlay thickness, with tolerance within 0-0.5mm |

Main Thicknesses | 3+3,4+4, 5+5 6+4,6+5,6+6,6+8 8+4,8+5,8+6,8+7,8+8 10+4,10+5,10+6,10+7,10+8,10+9,10+10,10+20 12+4,12+5,12+6,12+7,12+8,12+10,12+11,12+12 14+6,14+8,14+10,16+6,16+8,16+10 18+6,18+8,18+10,20+5,20+6,20+8,20+10,20+20,30+10,40+10 Customized. |

| Plate Size | Open arc welding wear plate:1400*3400mm Submerged arc welding wear plate:1400*3000mm, 1400*3500mm, 2100*3500mm. Customized |

| Place of Origin | China |

| Application | Mining,Steel,Cement,Power,Port,etc. |